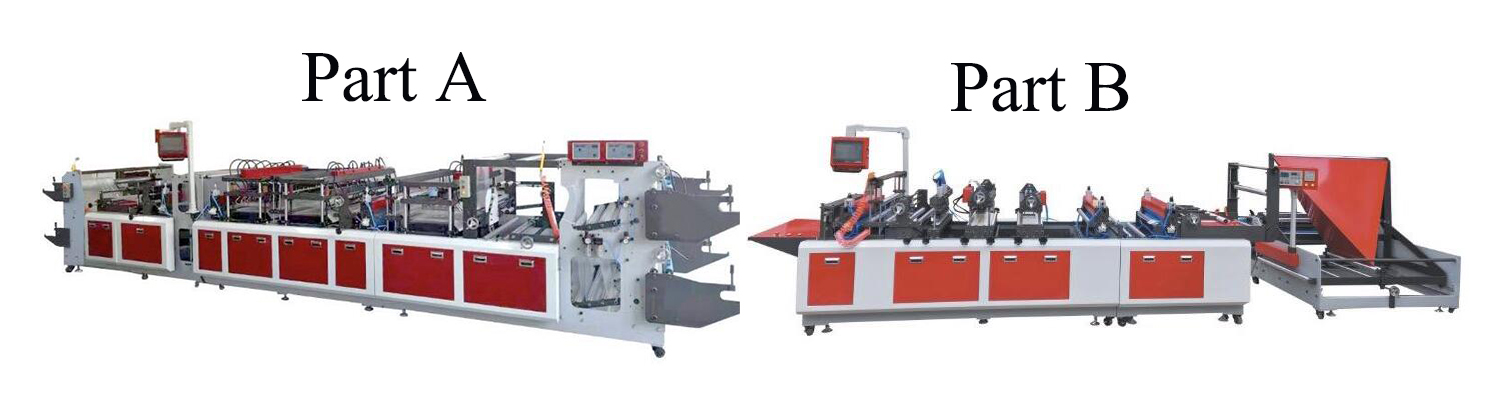

| Name: | Air Column Bag Making Machine (Part A+Part B) |

| Inquiry |

Product Description

APPLICATIONS

FEATURES

It is suitable for making all kinds of airbag, cushion bag, filling bag by PE Co-extruded film. The products are having the advantages of low cost, saving space, re-cycling, easy packing, manpower saving, no pollution and long time airtight for stock and transportation.

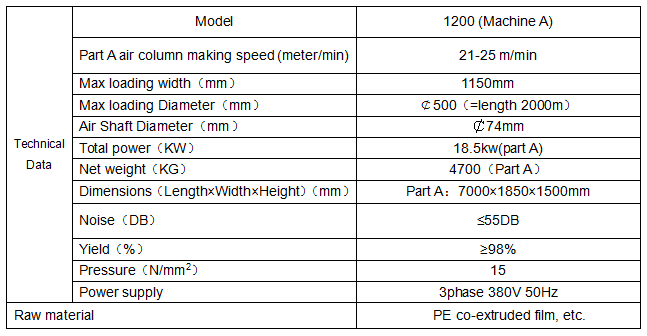

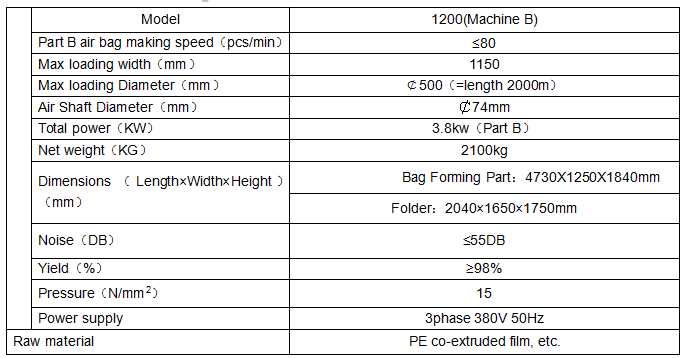

1. Automatic Machine controlled by PLC and Inverter. Easy operation control panel.

2.Parameter setting effect immediately, tracked by electronic eyes, smooth and accurate.

3.Widely frequency range of inverters are controlling the whole production line, stepless speed changing, individual release

and pick up motors make production more smooth and effective.

4.Release and pick up roll holders are using air expansion shaft, easy load and unload.

Hits: 【Print】

Related Products

Air Column Bag M...

Air Column Bag M...

Send Email

Send Email